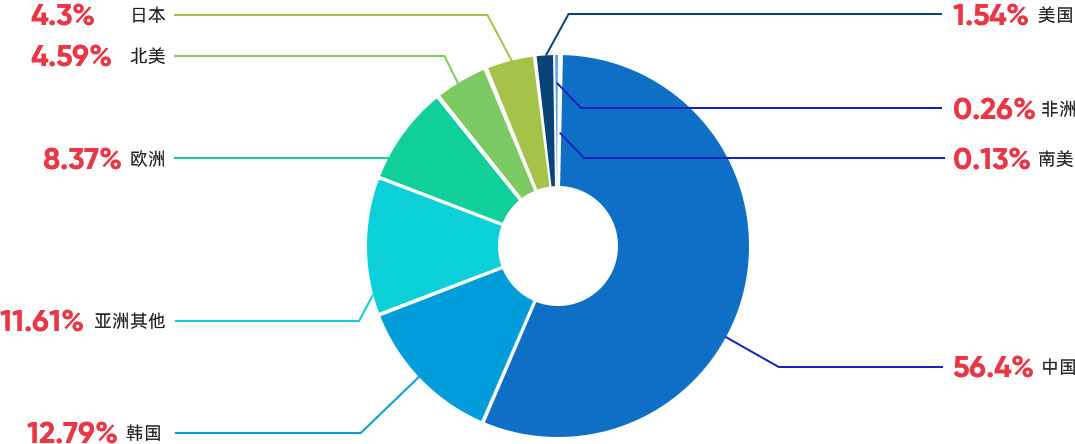

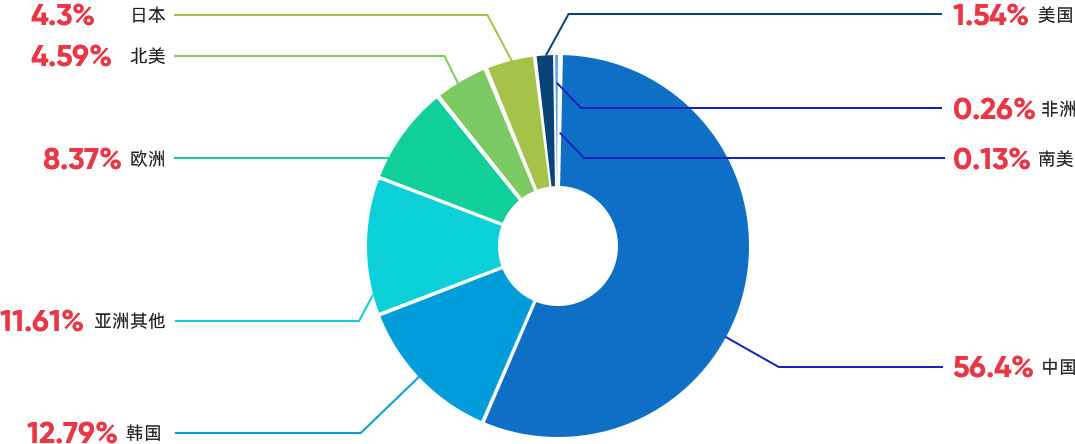

Market Distribution

Over the past 20 years, Aoshikang has employed a sales model that prioritizes direct sales with distribution as a secondary approach. This strategy has enabled the company to directly understand market needs through direct sales and to access specific customers and market areas through distribution, facilitating rapid market expansion and reduced operational costs. Aoshikang has subsequently established 27 sales and business teams in key global locations, including Seoul, South Korea; Tokyo, Japan; Singapore, France; and the United States. The establishment of business units in Japan, South Korea,France, and the United States, in particular, has opened up vast prospects and significant market potential for the company's business development and market penetration. Capitalizing on its strengths in technology, management, and efficiency, with support of Guangdong-based robust production capacity and new-generation circuit manufacturing model, Aoshikang plans to integrate various resources such as market, technology, personnel, and capital. This multi-level, comprehensive approach aims to enhance the company's capacity for sustainable development, industry status, and core competitive advantages, thereby providing all-encompassing services to customers worldwide.

At the beginning of 2021, Aoshikang established its third five-year plan and three major business strategies: the IET Strategy (IE + IT, integrating Industrial Engineering with Information Digitization), Talent Strategy, and Product Strategy. This initiative marked the start of comprehensive and deep reforms in the company's sales system, information technology development, and human resource construction. In 2021, Aoshikang ranked second globally in terms of growth rate among the top 40 PCB (Printed Circuit Board) companies worldwide, and first in the China region. Within the capital from the mainland China, Aoshikang was ranked eighth but held the top position among Hunan Province.